vår blogg

Fullpackad med fascinerande artiklar, användbara råd, tips och tekniker, vår blogg är det bästa stället att komma när du letar efter information om lim och tillverkningsmaterial.

Senaste blogginlägget

-

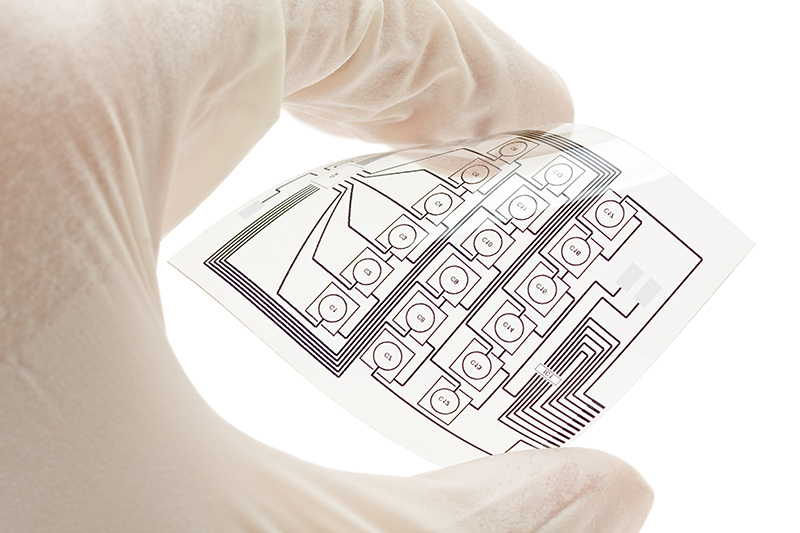

Smarta ytlösningar med tryckt elektronik

Vad är Smart Surface Solutions? Den pågående expansionen av megatrender som IoT och digitalisering driver efterfrågan på tryckta sensorer och antenner som är applicerbara på olika formade ytstrukturer. Som en branschledande leverantör av tryckta elektronikmaterial och tjänster utnyttjar Henkel dessa megatrender för att skapa smarta ytlösningar som inte är...